全自动封胶线有什么技术优势?

时间:2025-04-18 来源:http://freexvideosnow.com/ 发布人:昌盛机械

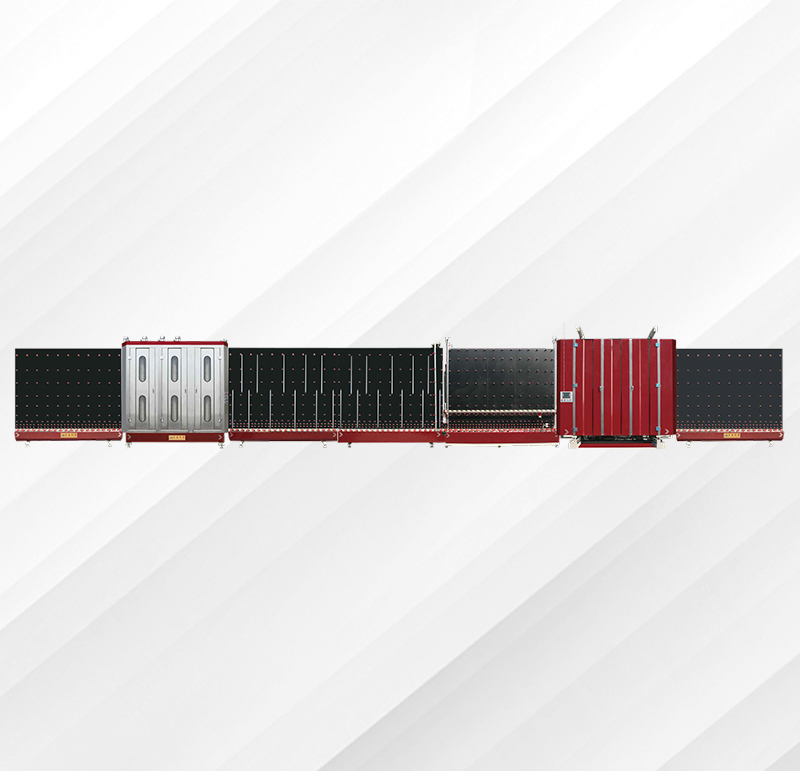

在制造业向智能化、自动化大步迈进的当下,全自动封胶线凭借其突出的技术优势,成为众多企业提升生产效能、保障产品质量的得力助手。尤其是在玻璃深加工、电子电器、汽车制造等对封胶工艺要求严苛的领域,全自动封胶线正重塑生产格局。

In the current era of intelligent and automated manufacturing, fully automatic sealing lines have become a powerful assistant for many enterprises to improve production efficiency and ensure product quality, thanks to their outstanding technological advantages. Especially in fields such as glass deep processing, electronic appliances, and automotive manufacturing that require strict sealing processes, fully automatic sealing lines are reshaping the production landscape.

高效生产,产能大幅跃升

Efficient production, significant increase in production capacity

全自动封胶线以高度集成化与自动化设计,显著压缩生产周期。其配备的高速伺服电机与精密传动系统,促使封胶头快速精准定位与移动,相比人工封胶,效率提升 3-5 倍。在汽车发动机缸体封胶环节,人工每小时仅能完成 30-50 件,而全自动封胶线每小时可处理 150-200 件。并且,它能实现 24 小时不间断作业,减少因人工疲劳、交接班造成的时间损耗,极大提高设备利用率与企业产能,充分满足大规模生产需求。

The fully automatic sealing line is designed with high integration and automation, significantly reducing the production cycle. The high-speed servo motor and precision transmission system equipped with it enable the sealing head to quickly and accurately position and move, which is 3-5 times more efficient than manual sealing. In the sealing process of automobile engine cylinder blocks, manual labor can only complete 30-50 pieces per hour, while the fully automatic sealing line can process 150-200 pieces per hour. Moreover, it can achieve 24-hour uninterrupted operation, reduce time loss caused by manual fatigue and shift handover, greatly improve equipment utilization and enterprise capacity, and fully meet the needs of large-scale production.

精准作业,质量稳定可靠

Accurate homework, stable and reliable quality

先进的视觉识别与闭环控制系统,是全自动封胶线精准运作的核心。设备内置高清工业相机与传感器,可实时捕捉工件位置、尺寸及表面特征,误差检测精度达 ±0.05mm。系统依据预设程序,自动调控封胶轨迹、出胶量与速度,确保胶线均匀、连续,杜绝漏胶、堆胶现象。以电子芯片封装为例,全自动封胶线能将胶层厚度精准控制在 0.1mm 以内,产品良品率提升至 99% 以上,有效降低因封胶质量问题导致的返修与报废成本。

The advanced visual recognition and closed-loop control system is the core of the precise operation of the fully automatic sealing line. The device is equipped with high-definition industrial cameras and sensors, which can capture the position, size, and surface features of the workpiece in real time, with an error detection accuracy of ± 0.05mm. The system automatically adjusts the sealing trajectory, dispensing amount, and speed according to the preset program, ensuring that the glue line is uniform and continuous, and preventing glue leakage and stacking. Taking electronic chip packaging as an example, the fully automatic sealing line can accurately control the thickness of the adhesive layer within 0.1mm, increase the product yield rate to over 99%, and effectively reduce the repair and scrap costs caused by sealing quality problems.

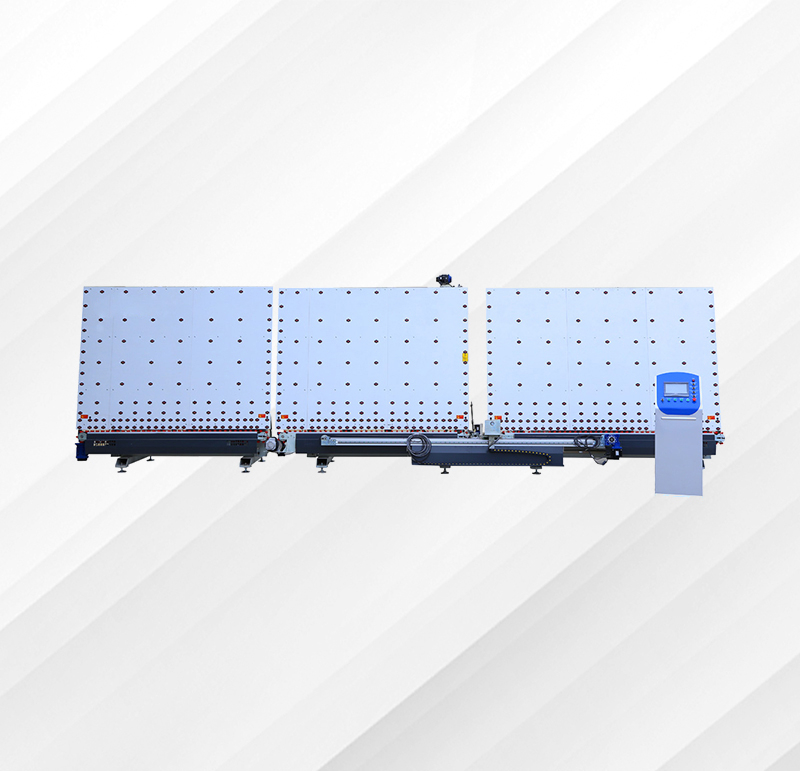

灵活适配,满足多元需求

Flexible adaptation to meet diverse needs

全自动封胶线具备出色的柔性生产能力,可快速切换不同产品的封胶工艺。通过模块化设计,更换封胶头、治具等组件仅需半小时,配合参数化编程,能适配多种规格、形状的工件。在新能源电池封装领域,同一条封胶线可满足方形、圆柱、软包等不同类型电池的封胶需求,企业无需为新产品投产额外购置设备,降低设备投资成本,提高产线通用性。

The fully automatic sealing line has excellent flexible production capacity and can quickly switch the sealing process of different products. Through modular design, it only takes half an hour to replace components such as sealing heads and fixtures. With parameterized programming, it can adapt to workpieces of various specifications and shapes. In the field of new energy battery packaging, the same sealing line can meet the sealing needs of different types of batteries such as square, cylindrical, and soft pack. Enterprises do not need to purchase additional equipment for the production of new products, reducing equipment investment costs and improving production line universality.

智能管控,优化生产流程

Intelligent management and optimization of production processes

借助工业物联网与大数据技术,全自动封胶线实现智能化管理。设备实时采集运行参数、出胶量、生产进度等数据,经云端平台分析处理,生成设备状态预警、维护提醒等信息。管理人员通过手机或电脑即可远程监控产线,及时调整生产计划。同时,系统对历史生产数据的分析,有助于优化封胶工艺参数,提升生产效率与产品质量,助力企业向数字化、智能化管理转型。

With the help of industrial Internet of Things and big data technology, the fully automatic sealing line achieves intelligent management. The device collects real-time data on operating parameters, glue output, production progress, etc., which is analyzed and processed by the cloud platform to generate equipment status warnings, maintenance reminders, and other information. Management personnel can remotely monitor the production line and adjust production plans in a timely manner through mobile phones or computers. At the same time, the analysis of historical production data by the system helps optimize the sealing process parameters, improve production efficiency and product quality, and assist enterprises in transitioning to digital and intelligent management.

本文由全自动封胶线友情奉献.更多有关的知识请点击:http://freexvideosnow.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 全自动封胶线有什么技术优势? 2025/04/18

- 中空玻璃生产线成本高,怎么选性价比高的? 2025/04/15

- 验收时才发现玻璃自爆,工期延误赔偿百万? 2025/04/14

- 中空玻璃加工设备的讲解 2025/04/12

- 毛刷式清洗机怎么使用 2025/04/11

- 中空玻璃加工设备核心是什么? 2025/04/10

- 全自动铝条折弯机如何设置更快,让编程更简单? 2025/04/09

- 双组份打胶机让胶水发挥最大威力 2025/04/08

- 卧式丁基胶涂布机的优势有什么 2025/04/07

- 封胶线麻烦?全自动封胶线了解一下 2025/04/01

当前位置:

当前位置:

产品分类Product categories

产品分类Product categories

联系我们Contact us

联系我们Contact us