卧式丁基胶涂布机的优势有什么

时间:2025-04-07 来源:http://freexvideosnow.com/ 发布人:昌盛机械

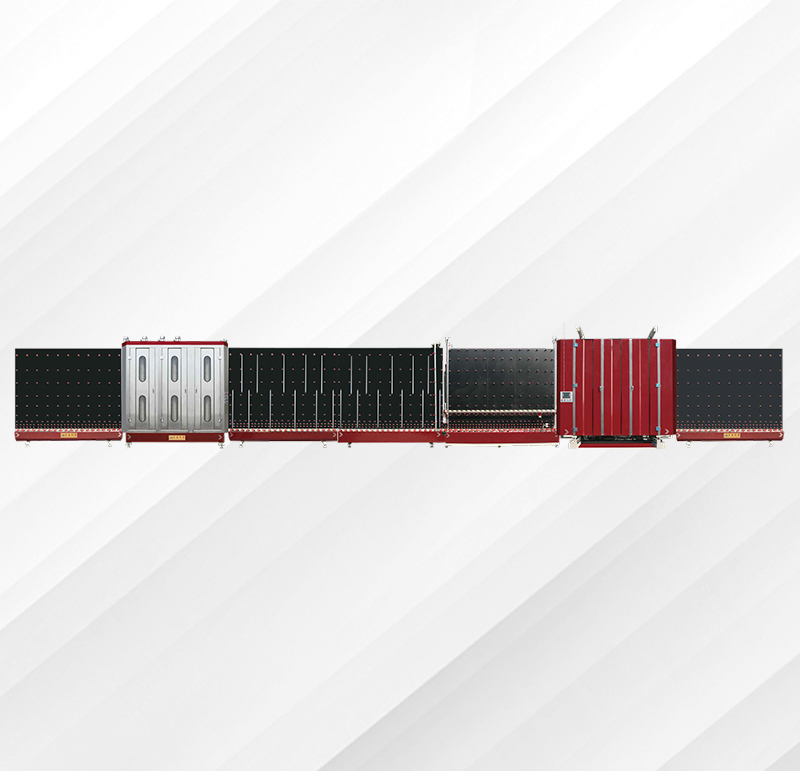

在汽车制造、建筑门窗、航空航天等领域,丁基胶作为高性能密封材料,其涂布质量直接影响产品的防水、隔音和使用寿命。卧式丁基胶涂布机凭借独特的结构设计和稳定性能,成为实现高效密封的关键装备。

In the fields of automobile manufacturing, building doors and windows, aerospace, etc., butyl rubber is used as a high-performance sealing material, and its coating quality directly affects the waterproof, soundproof, and service life of the product. The horizontal butyl rubber coating machine, with its unique structural design and stable performance, has become a key equipment for achieving efficient sealing.

一、结构原理:稳定运行的基础保障

1、 Structural principle: the basic guarantee for stable operation

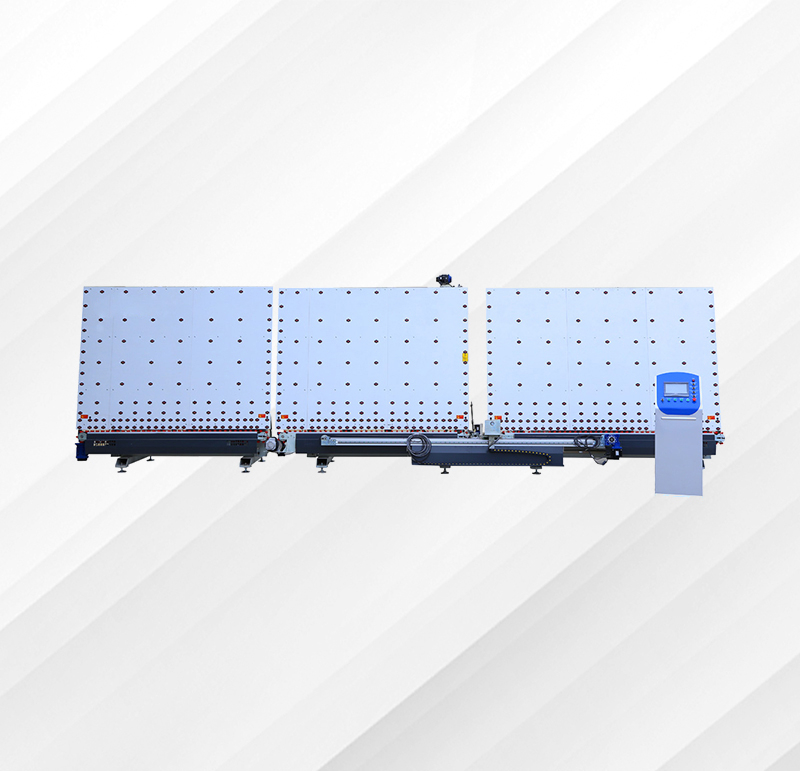

卧式丁基胶涂布机采用水平式结构设计,主要由胶箱系统、涂布头、传动机构和控制系统四部分组成。胶箱内置恒温加热装置,可将丁基胶保持在 120-150℃的熔融状态,确保胶水流动性。涂布头配备精密计量泵和可调节刮刀,通过伺服电机控制,实现 0.1-5mm 厚度范围内的精准涂布。传动机构采用同步带或齿轮齿条驱动,配合直线导轨,保证涂布头在移动过程中保持 ±0.05mm 的定位精度。控制系统集成 PLC 和人机界面,支持参数预设、实时监控和故障报警功能。

The horizontal butyl rubber coating machine adopts a horizontal structural design, mainly composed of four parts: the rubber box system, the coating head, the transmission mechanism, and the control system. The glue box is equipped with a constant temperature heating device, which can keep the butyl rubber in a molten state at 120-150 ℃, ensuring the fluidity of the glue. The coating head is equipped with a precision metering pump and an adjustable scraper, controlled by a servo motor to achieve precise coating within the thickness range of 0.1-5mm. The transmission mechanism adopts synchronous belt or gear rack drive, combined with linear guide rail, to ensure that the coating head maintains a positioning accuracy of ± 0.05mm during the movement process. The control system integrates PLC and human-machine interface, supporting parameter preset, real-time monitoring, and fault alarm functions.

这种结构设计使设备运行时振动更小,胶水涂布更均匀,特别适合对精度要求高的连续生产场景。例如在汽车玻璃生产线上,卧式涂布机可实现每小时 200 片以上的涂布速度,且边缘溢胶量控制在 0.3mm 以内。

This structural design results in less vibration during equipment operation and more uniform glue application, making it particularly suitable for continuous production scenarios that require high precision. For example, on the automotive glass production line, the horizontal coating machine can achieve a coating speed of over 200 pieces per hour, and the edge overflow amount is controlled within 0.3mm.

二、核心优势:性能提升的关键所在

2、 Core Advantage: The Key to Performance Improvement

1. 涂布精度的显著提高

1. Significant improvement in coating accuracy

相比传统手工涂布,卧式设备通过机械控制实现了质的飞跃。某实验室测试数据显示,手工涂布的厚度偏差在 ±0.5mm,而设备涂布可将偏差控制在 ±0.1mm,这对于需要均匀受力的密封结构至关重要。例如在建筑中空玻璃生产中,精准的胶层厚度能有效防止玻璃因应力不均而自爆。

Compared to traditional manual coating, horizontal equipment has achieved a qualitative leap through mechanical control. According to test data from a certain laboratory, the thickness deviation of manual coating is within ± 0.5mm, while equipment coating can control the deviation within ± 0.1mm, which is crucial for sealing structures that require uniform force. For example, in the production of insulated glass in buildings, precise adhesive layer thickness can effectively prevent the glass from bursting due to uneven stress.

2. 生产效率的倍数增长

2. Multiple growth of production efficiency

卧式设计允许更大幅面的工件通过,配合双工位交替作业,可实现 24 小时不间断生产。在某门窗型材厂的实测中,设备每小时可处理 150 米长的型材,是人工涂布效率的 8 倍以上。同时,设备的连续涂布特性避免了手工操作中常见的断点问题,产品合格率从 82% 提升至 97%。

The horizontal design allows larger workpieces to pass through, coupled with dual station alternating operation, achieving 24-hour uninterrupted production. In the actual test of a door and window profile factory, the equipment can process profiles up to 150 meters long per hour, which is more than 8 times the efficiency of manual coating. At the same time, the continuous coating characteristics of the equipment avoid common breakpoint problems in manual operations, and the product qualification rate has increased from 82% to 97%.

3. 材料适应性的全面增强

3. Comprehensive enhancement of material adaptability

通过调整温度、压力和刮刀角度,卧式涂布机可处理不同黏度的丁基胶。对于低黏度胶水(如用于电子元件密封的型号),设备可通过降低刮刀压力减少胶水飞溅;对于高黏度产品(如汽车挡风玻璃专用胶),则通过提高温度和增加计量泵转速保证涂布流畅。这种灵活性使其在不同行业都能发挥作用。

By adjusting temperature, pressure, and scraper angle, the horizontal coating machine can process butyl rubber of different viscosities. For low viscosity adhesives (such as those used for sealing electronic components), the equipment can reduce adhesive splashing by lowering the scraper pressure; For high viscosity products (such as car windshield adhesive), smooth coating is ensured by increasing the temperature and the speed of the metering pump. This flexibility allows it to play a role in different industries.

本文由卧式丁基胶涂布机友情奉献.更多有关的知识请点击:http://freexvideosnow.com我们将会对您提出的疑问进行详细的解答,欢迎您登录网站留言.

This article is dedicated to friendship For more information, please click: We will provide detailed answers to your questions. You are welcome to log in to our website and leave a message

- 中空玻璃加工设备的讲解 2025/04/12

- 毛刷式清洗机怎么使用 2025/04/11

- 中空玻璃加工设备核心要素 2025/04/10

- 全自动铝条折弯机如何设置更快,让编程更简单? 2025/04/09

- 双组份打胶机让胶水发挥最大威力 2025/04/08

- 卧式丁基胶涂布机的优势有什么 2025/04/07

- 封胶线麻烦?全自动封胶线了解一下 2025/04/01

- 中空玻璃加工设备:建筑节能革命的核心引擎 2025/03/31

- 中空玻璃生产线的概述 2025/03/28

- 全自动铝条折弯机安全操作流程 2025/03/24

当前位置:

当前位置:

产品分类Product categories

产品分类Product categories

联系我们Contact us

联系我们Contact us